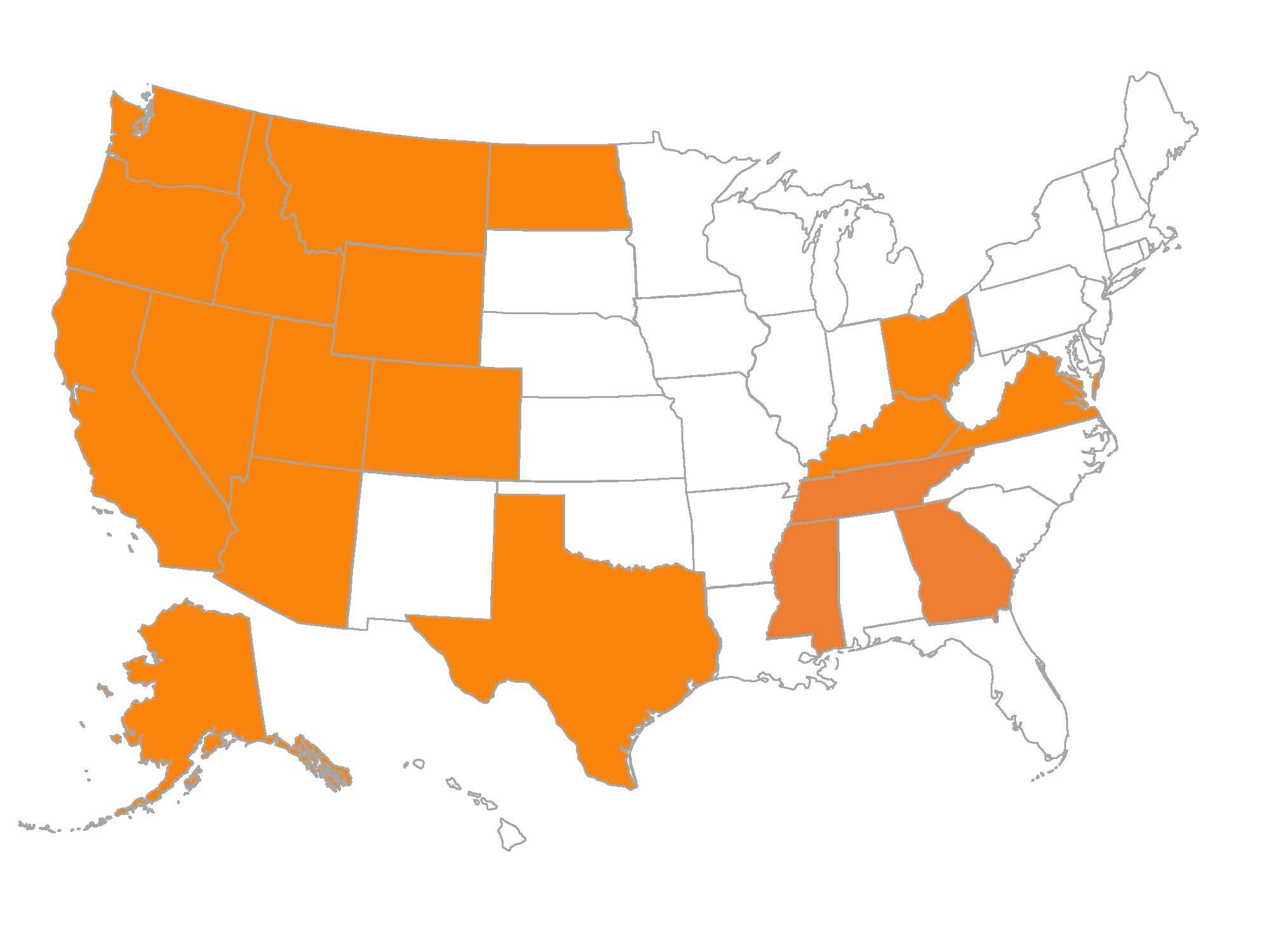

Alaska • Arizona • California • Colorado • Georgia • Idaho • Kansas • Kentucky • Mississippi • Montana • Nevada • North Dakota • Ohio • Oregon • Texas • Tennessee • Utah • Virginia • Washington • Wyoming • …. and your state is next!

WHY CHOOSE ARI?

🔹 Over 5.6 GW of Utility‑Scale Solar Pre‑Drilling Project Completions

ARI has now exceeded 5.6 GW of installed solar pre‑drilling projects across the U.S., showcasing unparalleled fleet capacity and execution consistency in solar site development.

🔹 DOL‑Registered Apprenticeship Program

ARI proudly hosts one of the nation’s first Department of Labor–registered apprenticeships for drilling—training rock drill operators via a structured, hands-on, and credentialed pathway

🔹 Utility‑Scale Solar Expertise

Our specialists handle utility‑scale solar pile pre‑drilling (up to 16″ diameter), resolving pile refusal scenarios to maintain project timelines

🔹 ENR Top 600 Specialty Contractor

Nationally ranked by Engineering News-Record for performance and specialty trade execution across civil, energy, and infrastructure sectors.

🔹 Nationwide Licensing via NASCLA

With the completion of the NASCLA Accredited General Contractors Exam, ARI can fast‑track licensing in 16+ states—if your state is not one of the 18 states listed above, we can fast-track registration.

🔹 Industry-Leading Safety Performance

ARI maintains an exceptional Experience Modification Rate (EMR) of 0.73, significantly outperforming the industry average. Notably, we have achieved zero OSHA-recordable incidents across all our utility-scale solar projects, reflecting our rigorous safety protocols and commitment to operational excellence.

🔹 Full Civil & Infrastructure Scope

ARI provides precision drilling & blasting for roads, utilities, wind‑turbine foundations, dam/bridge demolition, trench‑line blasting, mines, rock quarry development, emergency slide repair, and portable crushing—covering the complete site development lifecycle

🔹 Tech‑Driven Precision & Safety

Our fleet includes GPS‑guided SmartROC drill rigs, Measure–While–Drilling systems, GPS Rovers, drone volumetric surveys, electronic detonation (1 ms timing), and remote operator stations, bringing enhanced accuracy, safety, and productivity to every project .

🔹 100% Cherokee Nation–Owned & Buy‑Indian Qualified

ARI is a certified Indian Economic Enterprise, led by Cherokee Nation members Kris (President) and Katie (CEO), making us eligible for Buy Indian Act projects across drilling, blasting, and portable crushing

🔹 Proven Size & Experience

With 46+ years of rock drilling and blasting experience, ARI operates across more than 18 states, backed by a high‑capability fleet ready for both high‑volume quarrying and precision solar pre‑drilling.

SERVICES OVERVIEW

• Solar Pre‑Drilling

Utility‑scale pile pre‑drilling with high‑precision capabilities to mitigate pile refusal.

• Advanced Wide-Diameter Drilling with LoDril™ (up to 60″)

ARI’s excavator-mounted LoDril™ is capable of drilling up to 60 inches in diameter and 45 ft depths. Ideal for large socketed installations—such as foundation drilling for power poles, monopoles, and solar Tracker supports—these units operate in tight-access zones, under low bridges, or along transmission rights-of-way.

• Civil & Infrastructure Drilling & Blasting

ARI delivers precision-controlled subsurface preparation for roads, utilities, mines, quarries, wind foundations, dam/bridge demolition, emergency slide repair—and extends our capabilities to high‑profile, urban and sensitive site projects such as data centers, schools, hospitals, and close‑proximity commercial developments.

Sensitive Urban & Infrastructure Projects

We excel in blasting operations near critical facilities, employing seismic monitoring, electronic detonation sequencing, and precise drill layouts—all in compliance with noise, vibration, and safety restrictions in dense urban and sensitive environmentsHigh-Profile Data Centers & Utility Sites

ARI has supported data center and substation site work, managing blast planning and execution within tight zones under low-clearance and in proximity to vulnerable equipment.Structural Demolition & Excavation

We have performed controlled blasting for dam and bridge removal, tunnel pre‑cuts, trenching adjacent to active infrastructure, and emergency landslide remediation—maintaining full control over vibration, fly‑rock, dust, and airblastComprehensive Monitoring & Technology Use

Our use of drone-enabled volumetric surveying, GPS-guided SmartROC drills, and electronic detonation with millisecond precision enables rigorous monitoring and proactive adjustments to meet the most demanding site constraints

Why This Matters

Minimized Disruption: Real-time vibration control ensures the integrity of nearby structures and sensitive operations.

Certified Compliance: We adhere to OSHA/MSHA protocols and utilize seismic monitoring to meet or exceed local and national regulations.

Trusted by High-Stakes Projects: When schedules, safety, and infrastructure sensitivity are non-negotiable, ARI is the proven partner of choice.

Technology & Innovation

Smart Drills: Automated GPS hole navigation, Measure‑While‑Drilling feedback

Drone & Survey Tech: Post-drill bore tracking, Pre/post blast volumetrics, fragmentation monitoring

Electronic Detonation: 1‑ms precision, minimized vibration, improved safety

Autonomous Equipment: Remote dozing enhances operator safety and site efficiency

Real-Time Daily Reporting & Transparency: ARI provides instant pre-shift and post-shift reporting of safety inspections, production metrics, and site conditions via mobile dashboards—delivering transparent communication of progress and roadblocks in real time, supporting proactive site management and decision-making

Digital Twin Site Modeling

Virtual Replication of Your Project

We build digital twin models for each project site—creating dynamic, near real-time digital replicas that mirror actual site conditions and drill plans. This virtual model is continuously updated using field data to reflect the evolving state of the sitePre‑Drill Planning & Simulation

Engineers use these models to optimize blast and drilling layouts before boots hit the ground. Through “what-if” scenarios, we can simulate penetration rates, fragmentation outcomes, and downstream crusher throughput—identifying potential issues before they occurMeasure‑While‑Drilling Integration

Field data from SmartROC GPS guidance and Measure‑While‑Drilling tools gets fed back into the digital twin, enabling real-time adjustments and continuous performance improvementsLifecycle Optimization & Data-Driven Decision Making

Our digital twins support ongoing monitoring—project to post-project. They help detect deviations, refine blast timing via electronic detonation, and optimize material flow. This results in safer, more efficient, and cost-effective operations

Why THIS Matters

By seamlessly linking field operations with virtual modeling, ARI empowers clients with insight and control rarely seen in drilling and blasting—minimizing risk, maximizing predictability, and delivering smarter project outcomes.

PORTABLE ROCK CRUSHING

Aggregate Resource Crushing, LLC provides portable rock crushing services in rock quarries throughout Oregon. ARC primarily exists to service the overflow work of other rock crushing companies.

Construction Aggregates

Aggregate Resource Industries offers crushed rock for sale to the general public in its quarries throughout Lane, Linn, and Benton counties. Crushed quarry rock of all sizes and landscape rock can be purchased at our Oregon rock quarries in Creswell, Halsey/Harrisburg, Philomath, and Florence.